-

tel:

+86 21-66786578 -

email:

novasara@novachn.cn

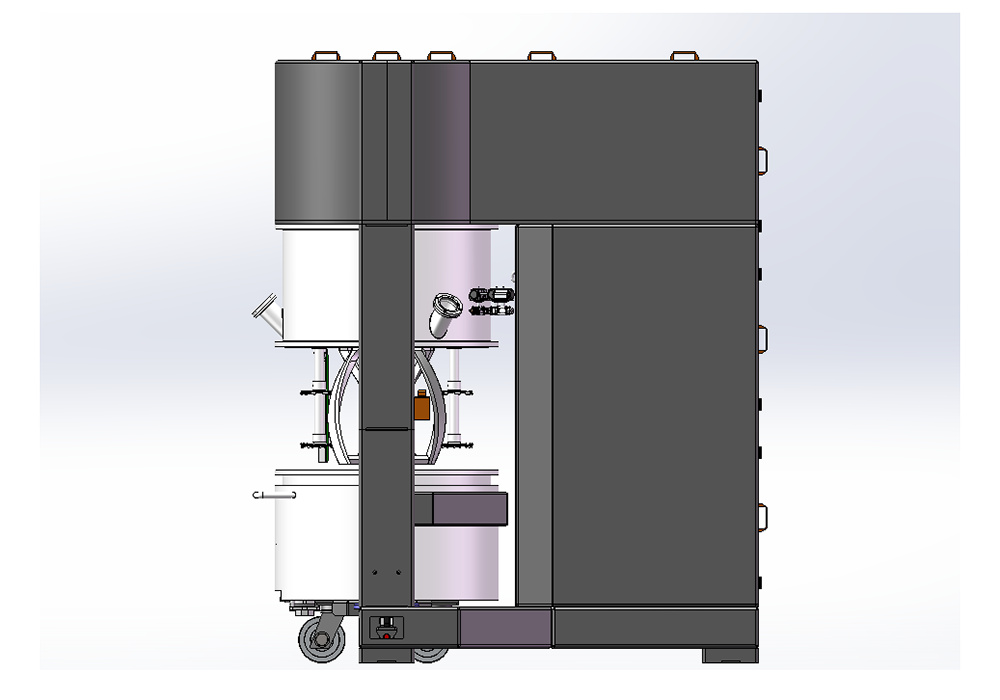

Planetary Mixer

The performance characteristics of dual planetary mixer are that the tank can be heated by electricity, steam, water and oil. The unique temperature detection device on the shaft ensures that the material temperature error is less than ±1℃. Clamping, bottom clamping and jacket inner tube, guide plate can be cooled. The rotation of the mixing pulp in the tank adopts frequency control of motor speed (frequency conversion motor). Different speed can be selected according to different process and viscosity. The speed measurement system directly gives the current speed of different agitators.

Double Planetary Mixer from NOVA is very different from other manufacturers

|

Additional Parts |

Characteristics |

NOVA |

Others |

Patent |

|

Decentralized mechanism circulating cooling system |

The decentralized mechanism of the double planet mixer is added with a decentralized circulating |

Yes |

No |

Patent for invention |

|

Planetary sealing oil tank and upper barrel seal |

The structures are added to prevent dust from entering the planet structure under various |

Yes |

No |

Utility model |

|

Planet mechanism grease filling and planet sealing oil tank |

The structure of planet mechanism grease filling and planet sealing oil tank are added, |

Yes |

No |

Utility model |

|

Automatic insertion and removal mechanism for |

It solves the negligence of manual plugging, |

Yes |

No |

Utility model |

Working Principle

A viscous mixer is fitted with a low-speed mixing component and a high speed dispersion component.

A low-speed mixing component adopts planetary gear drive.

The paddle revolves both round the barrel and on its own axis, which makes the material move up

and down to achieve the desired mixing effect in a short time.

The high - speed dispersing parts rotate with the planetary frame,

and they revolve on its own axis at high speed.

The material is strongly sheared and dispersed.

The effect is several times that of an ordinary mixer.

The dispersing parts are divided into the type of single

dispersing shaft and dual dispersing shaft.

Customers may choose according to their needs.

Two double - frame agitators revolve both round the barrel and on its own axis.

It can be equipped with more than one mixing barrel and operate with many barrels.

It is more convenient to discharge material with pressure feeder.

Technical Parameters

|

Model |

Volume |

Cylinder Diameter |

Dispersing Power |

Speed |

Stirred Power |

Revolution |

Rotation |

Lift |

Disc Diameter |

|

|

L |

mm |

kW |

rpm |

kW |

rpm |

rpm |

mm |

mm |

|

NYXJ-20 |

20 |

350 |

2.2 |

2880 |

1.5 |

48 |

100 |

450 |

70 |

|

NYXJ-30 |

30 |

400 |

3 |

2880 |

2.2 |

83 |

82 |

550 |

80 |

|

NYXJ-60 |

60 |

500 |

11 |

2880 |

7.5 |

50 |

80 |

650 |

110 |

|

NYXJ-100 |

100 |

596 |

15 |

2880 |

11 |

60 |

90 |

800 |

110 |

|

NYXJ-200 |

200 |

750 |

22 |

2880 |

15 |

52 |

83 |

900 |

150 |

|

NYXJ-300 |

300 |

836 |

30 |

2880 |

22 |

40 |

65 |

1000 |

150 |

|

NYXJ-500 |

500 |

1000 |

45 |

2880 |

37 |

35 |

56 |

1200 |

200 |

|

NYXJ-1000 |

1000 |

1266 |

55 |

1440 |

45 |

40 |

65 |

1400 |

250 |

|

NYXJ-1500 |

1500 |

1620 |

75 |

1440 |

45 |

40 |

65 |

1400 |

250 |

Product Application

It is suitable for liquid and liquid, solid and liquid materials’ mixing, reaction, dispersion, dissolution, homogenization, emulsification and other processes in the field of polymer lithium ion battery liquid and liquid lithium ion battery liquid, electronic electrode paste, adhesives, plastic mould, silicone sealant, polyurethane sealant, anaerobic adhesive, printing ink, paint, cosmetics, ointment, such as electronic, chemical, food, pharmaceutical, building materials, the pesticide industry and etc.

Applicable fields:Other fine chemical industry ,Adhesive agent , New materials , Ink/dye , Electronic chemicals , Food addition