-

tel:

+86 21-66786578 -

email:

novasara@novachn.cn

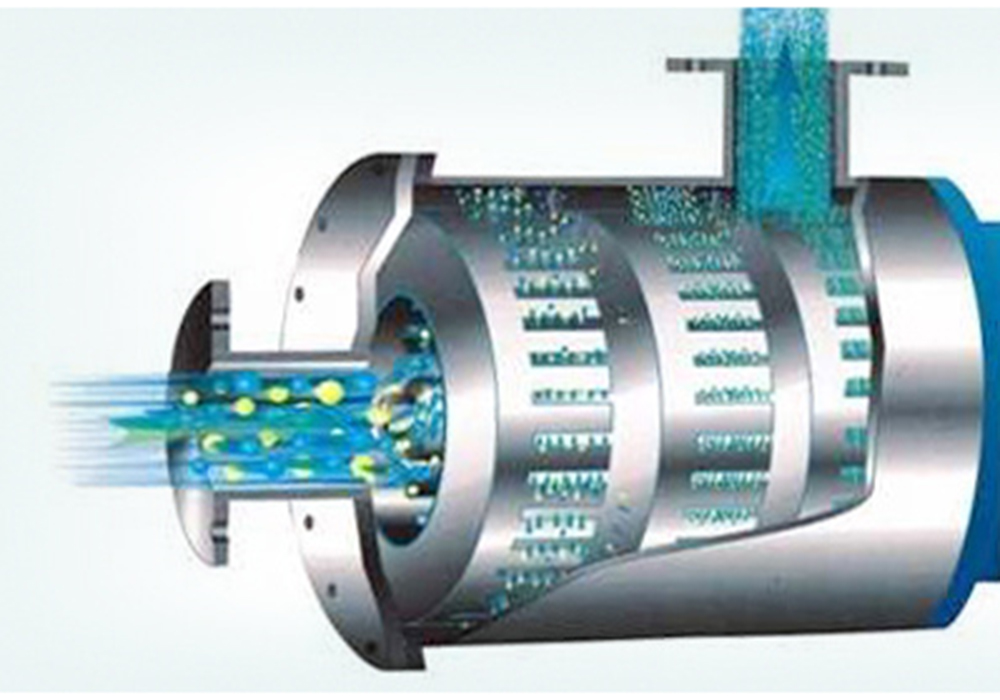

Three-stage Emulsion Pump

The three-stage high-shear emulsifier is a continuous production type emulsifier with high efficiency. It processes materials in continuous production or circulation of fine materials. The motor drives the rotor to rotate at high speed. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result. As a result, the materials become stable emulsion. It can be equipped with materials transfer pump in front of it to make it suitable for materials with mid-and-high viscosity. The materials are thoroughly dispersed and sheared after going through it. It is characterized in low noise and stable running, short transfer distance and low head.

Working Principle

The three-stage high shear emulsion pump adopts horizontal structure. Three groups of rotators and stators are installed in the long and narrow working chamber, and the rotators and stators are coupled and precisely matched; The motor drives the intermediate shaft to run at a high speed. The rotor stator forms a vacuum. The material is sucked into the rotor stator cavity from the inlet. The powerful kinetic energy causes the rotor to generate a very high linear speed, which makes the material fly out after a strong impact, crushing, centrifugation, liquid layer friction, and strong shear between the rotor and stator gaps. Under the action of various directional forces, strong turbulence is generated, and the material flows out of the outlet, thus making the immiscible solid The liquid phase, gas phase and other media are uniformly fine, dispersed and emulsified in an instant. The equipment can be operated repeatedly to make the products reach stable and high-quality products.

Technical Parameters

|

Model |

Power |

Speed |

Capacity |

Size |

Weight |

|

|

kW |

rpm |

m3/h |

mm |

kg |

|

NSRB-4 |

4 |

2880 |

2 |

1300×300×480 |

320 |

|

NSRB-7.5 |

7.5 |

2880 |

4 |

1380×300×480 |

350 |

|

NSRB-11 |

11 |

2880 |

8 |

1620×380×480 |

370 |

|

NSRB-15 |

15 |

2880 |

12 |

1620×380×480 |

380 |

|

NSRB-18.5 |

18.5 |

2880 |

15 |

1680×380×480 |

420 |

|

NSRB-22 |

22 |

2880 |

18 |

1680×380×480 |

450 |

|

NSRB-30 |

30 |

2880 |

24 |

1800×450×480 |

500 |

|

NSRB-37 |

37 |

2880 |

30 |

1880×520×540 |

550 |

|

NSRB-45 |

45 |

2880 |

45 |

1880×520×540 |

600 |

|

NSRB-55 |

55 |

2880 |

60 |

2340×650×700 |

680 |

Product Application

It is suitable for dispersion, emulsification and homogenization of products in biological, pharmaceutical, food, paint, ink, textile auxiliaries, cosmetics, lubricants, pesticides and other industries.

Applicable fields:Other fine chemical industry , Biology/Medicine , Ink/dye , Pesticides , Food addition , Coating